Carnegie Mellon University | 2023

Cornering Aerodynamics Analysis of a Formula SAE Race Car

Quantifying aerodynamic performance under straight-line and cornering flow conditions

Context

In Formula SAE, overall performance is driven primarily by cornering behavior, where available lateral grip limits vehicle speed more than straight-line acceleration. Aerodynamic downforce plays a key role by increasing tire normal force and improving cornering capability.

Despite this, aerodynamic development is commonly performed using straight-line CFD simulations due to their simpler domains and boundary conditions. While effective for relative design comparison, these simulations do not explicitly capture the turning flow field experienced during steady-state cornering.

This project examines how aerodynamic performance changes when the vehicle is subjected to a lateral velocity gradient representative of steady-state cornering, and evaluates how reliably straight-line CFD results reflect cornering-relevant aerodynamic behavior.

Approach

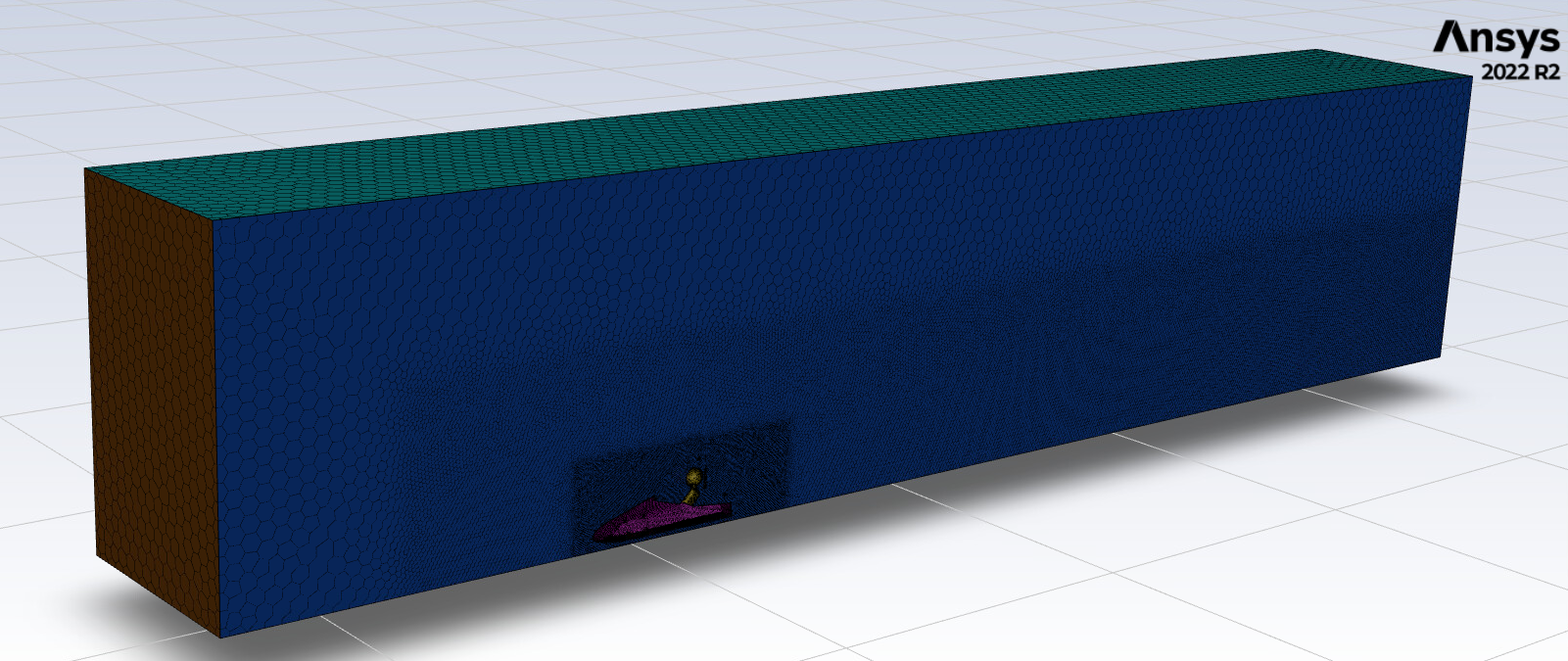

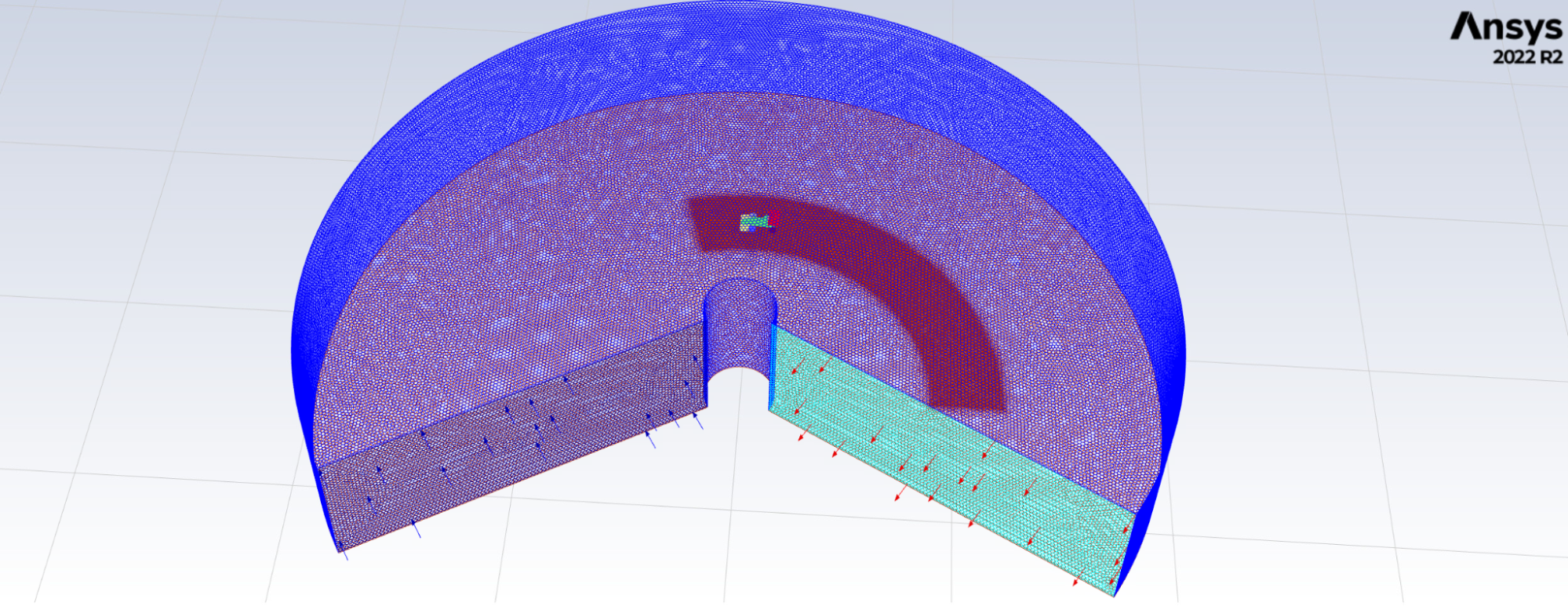

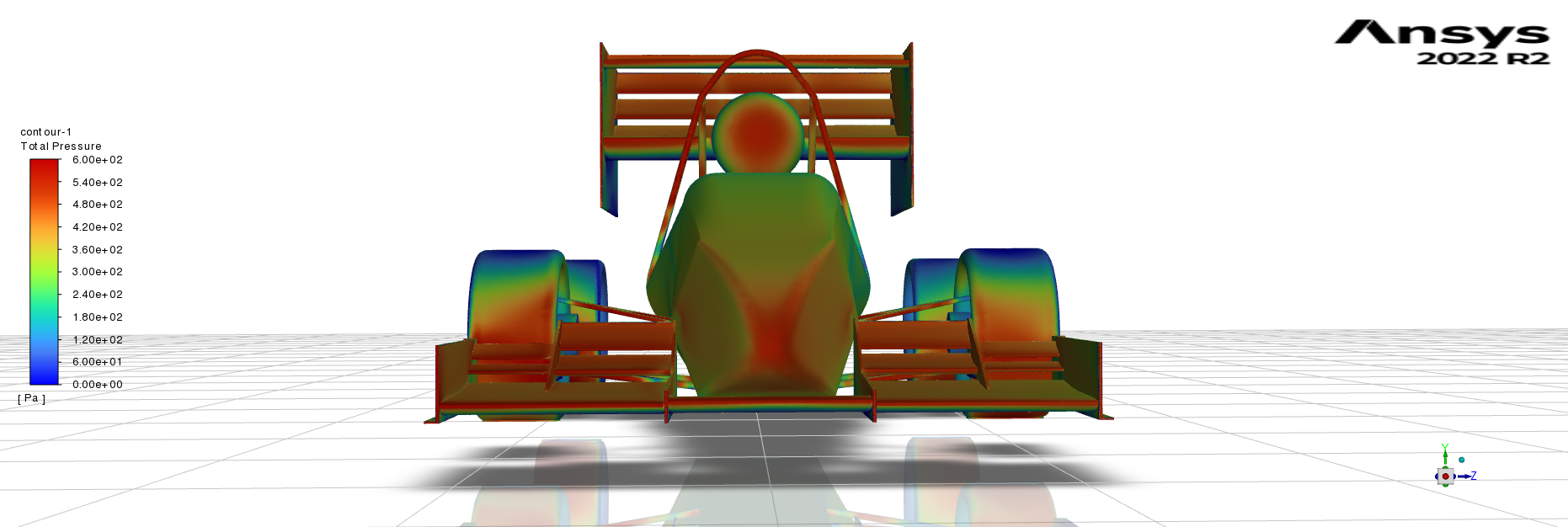

The study compares aerodynamic performance under conventional straight-line flow and steady-state cornering flow using two distinct CFD domain setups. Straight-line simulations were performed in a rectangular domain with uniform inlet velocity and symmetry applied, while cornering simulations used a curved, pie-shaped domain with a prescribed lateral velocity gradient across the vehicle width.

The straight-line case leveraged geometric symmetry and was modeled on a half-car, whereas the cornering configuration required a full-car model due to inherent flow asymmetry. All simulations used consistent turbulence modeling, discretization schemes, and boundary conditions to isolate the effect of turning flow.

Because the cornering domain introduces a spatial variation in local flow velocity, absolute force comparisons are not directly equivalent between cases. Aerodynamic performance was therefore evaluated primarily using the downforce-to-drag ratio, which provides a consistent and physically meaningful metric for comparing aerodynamic efficiency across straight-line and cornering conditions.

Implementation & Tools

Geometry and Domain Setup

- Simplified but aerodynamically representative CAD model including front and rear wings, chassis, driver body, and wheels

- Watertight geometry preparation to ensure robust volume meshing and consistent preprocessing across all configurations

- Rectangular straight-line domain with symmetry applied and curved pie-shaped domain for cornering flow, balancing computational cost with physical fidelity

CFD Solver and Physics

- ANSYS Fluent pressure-based coupled solver for steady-state external aerodynamics

- Incompressible RANS formulation with k-omega SST turbulence model, suitable for adverse pressure gradients and separated flow

- Second-order spatial discretization schemes to reduce numerical diffusion

- Boundary conditions including moving ground, rotating wheels, and velocity inlet with imposed lateral gradient for cornering cases

Mesh Strategy and Compute

- Watertight geometry meshing workflow using poly-hexcore volume meshes for efficient resolution of large external flow domains

- Boundary layer resolution targeting first cell heights of approximately 0.5 mm and y-plus values around 30 for wall-resolved RANS modeling

- Mesh sizes ranging from approximately 8 million to 21 million cells depending on configuration and domain extent

- All simulations executed on the Bridges-2 high-performance computing cluster to support large-scale parametric runs

Key Results

Straight-line baseline: In straight-line flow, the aerodynamic package produces substantial downforce relative to the no-aero configuration. Activating DRS primarily reduces drag, with only a modest effect on overall aerodynamic efficiency.

Straight-Line Aerodynamic Performance (20 m/s)

| Configuration | Downforce (N) | Drag (N) | Downforce / Drag |

|---|---|---|---|

| No aero | -47 | 117 | -0.40 |

| Aero, DRS active | 416 | 232 | 1.80 |

| Aero, DRS inactive | 599 | 348 | 1.72 |

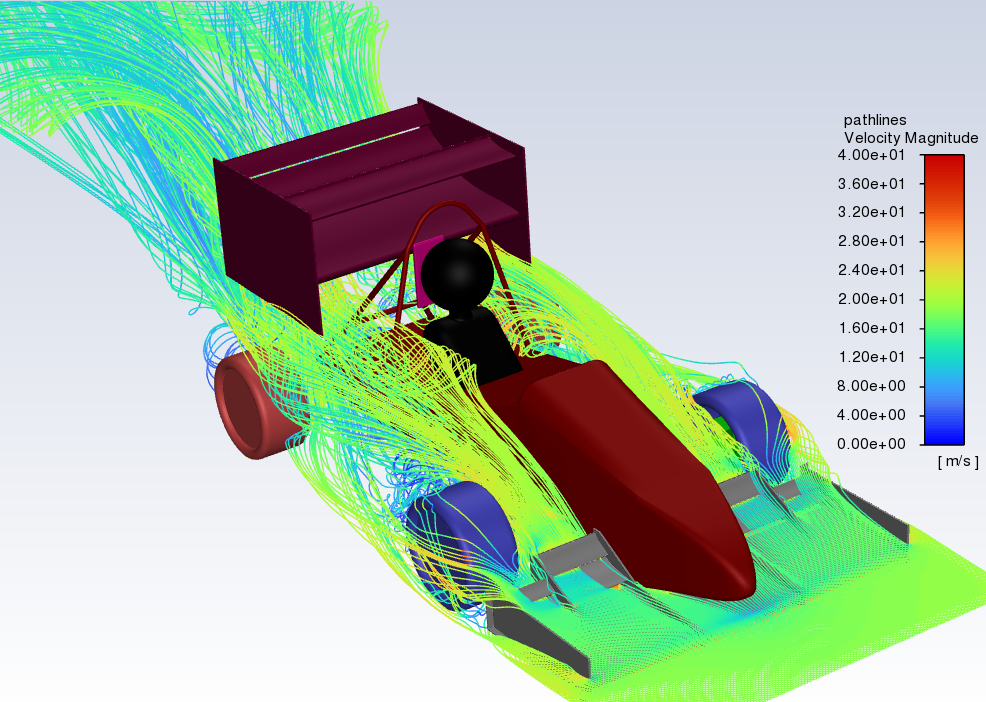

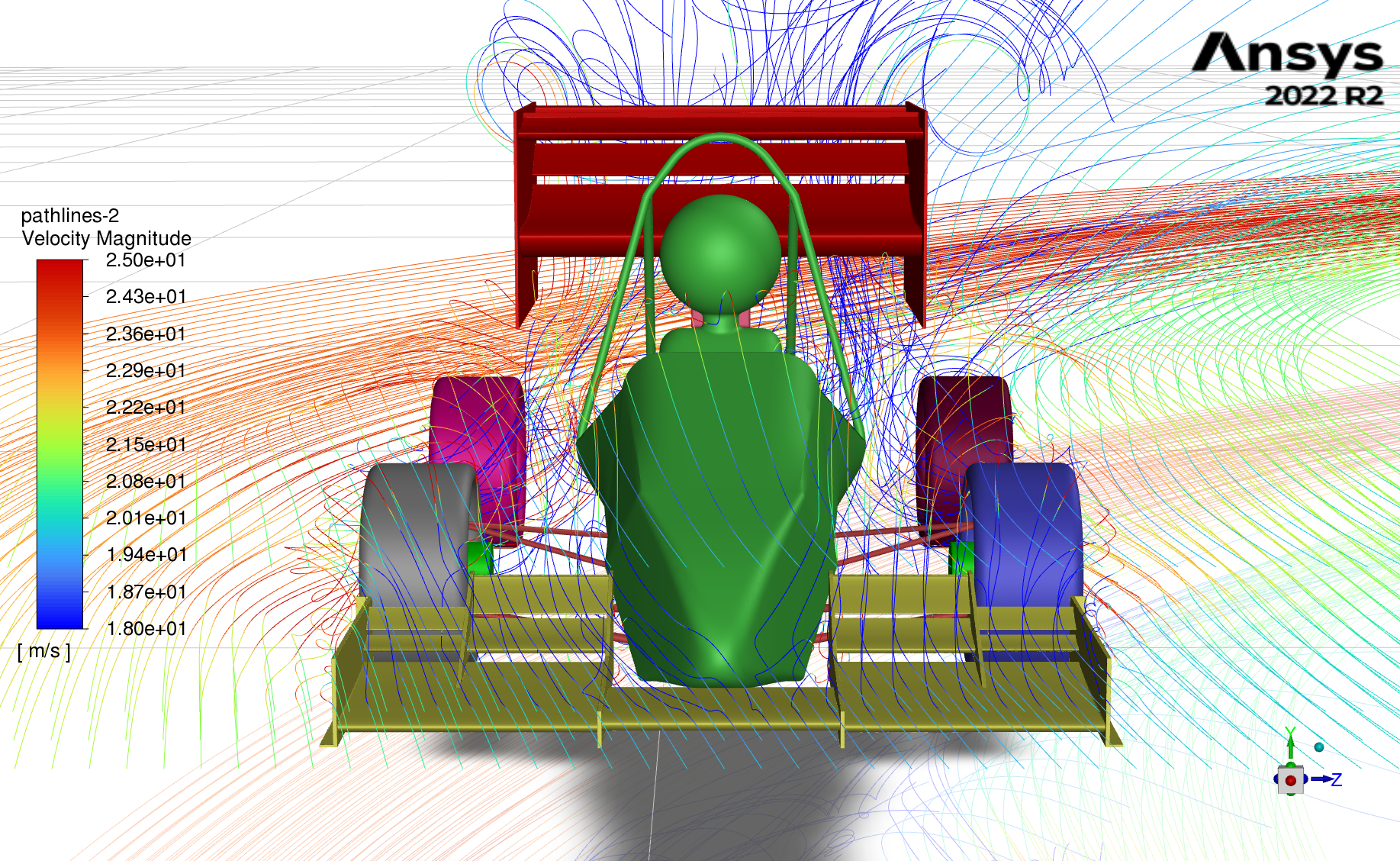

Cornering flow behavior: Under steady-state cornering conditions, downforce continues to scale predictably with vehicle speed. However, flow asymmetry alters the pressure distribution and wake structure relative to straight-line cases.

Cornering Aerodynamic Performance

| Velocity (m/s) | Downforce (N) | Drag (N) | Downforce / Drag |

|---|---|---|---|

| 10 | 163 | 100 | 1.63 |

| 15 | 373 | 225 | 1.66 |

| 20 | 675 | 404 | 1.67 |

| 30 | 1556 | 915 | 1.70 |

Key comparison: Across all tested speeds, cornering flow produces a consistent reduction in aerodynamic efficiency relative to straight-line simulations, despite similar downforce scaling trends.

Straight-Line vs Cornering Comparison

| Velocity (m/s) | Straight-Line D/D | Cornering D/D | Reduction |

|---|---|---|---|

| 10 | 1.70 | 1.63 | 2.5% |

| 15 | 1.70 | 1.66 | 2.6% |

| 20 | 1.72 | 1.67 | 2.9% |

| 30 | 1.74 | 1.70 | 2.4% |

Analysis & Insights

Across all tested speeds, cornering flow produces a consistent reduction in aerodynamic efficiency relative to straight-line simulations, despite similar trends in downforce scaling with velocity. This indicates that flow curvature primarily affects drag rather than fundamentally altering the downforce-generating mechanisms.

The observed efficiency reduction is modest in magnitude, suggesting that straight-line CFD simulations remain effective for comparative aerodynamic design, provided their limitations are understood. However, the asymmetric pressure distribution and wake structure under cornering flow highlight effects that are not captured by symmetric straight-line models.

From a design perspective, these results support the use of straight-line simulations for early-stage design iteration, while demonstrating the value of cornering-flow CFD as a targeted validation tool for bounding modeling assumptions and assessing aerodynamic robustness under realistic operating conditions.

What This Demonstrates

- Design and execution of controlled CFD studies to isolate specific physical effects

- Application of turbulence modeling and boundary layer resolution in large-scale external aerodynamics

- Interpretation of asymmetric flow fields and their impact on aerodynamic performance metrics

- Use of dimensionless ratios to enable fair comparison across non-uniform flow conditions

- Engineering judgment in balancing modeling fidelity, computational cost, and decision relevance

- Execution of high-performance computing workflows for production-scale simulation campaigns